Acoustic Cleaning

Keep Surfaces clean...

Since 23 years Hartge stands for professional support in relation to all aspects of acoustic cleaning: From detailed analysis via our consulting service through to professional realization. In doing so, we associate precise handcraft with state-of-the-art techniques and fulfill the highest quality demands.

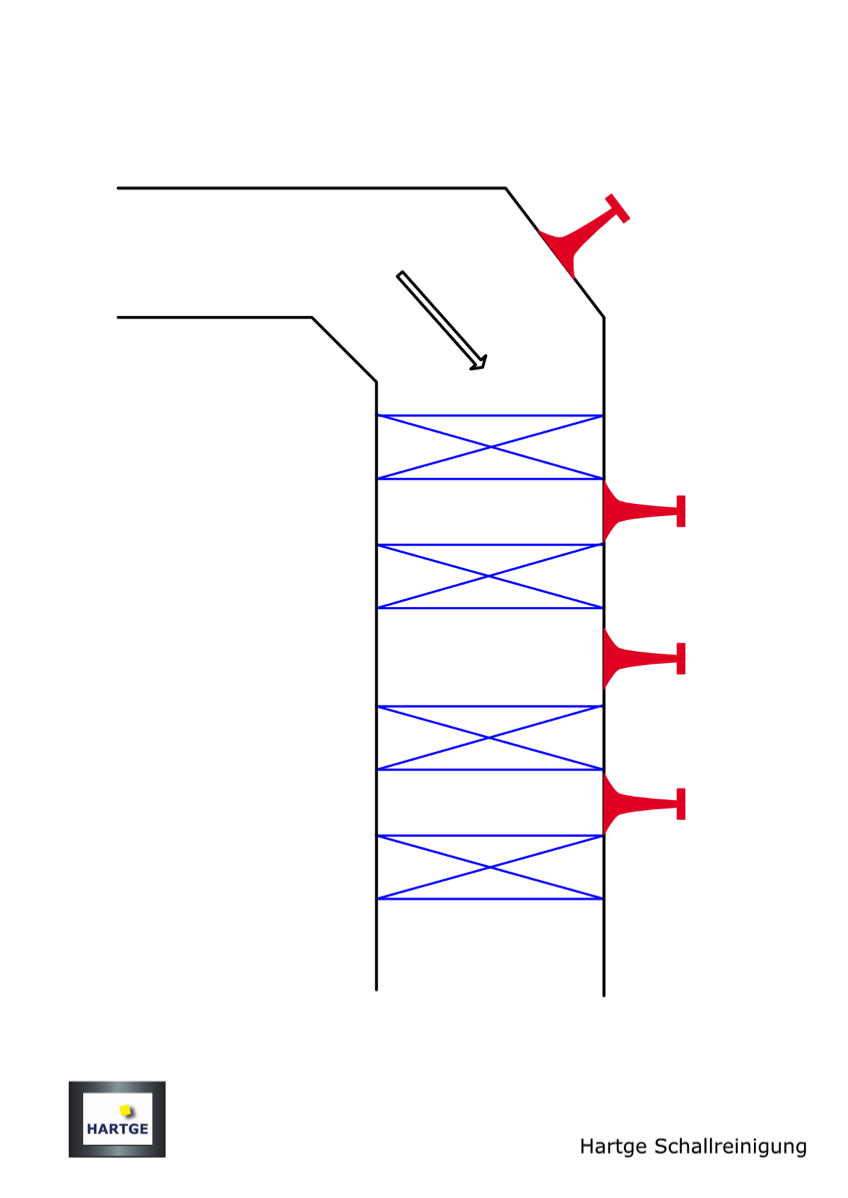

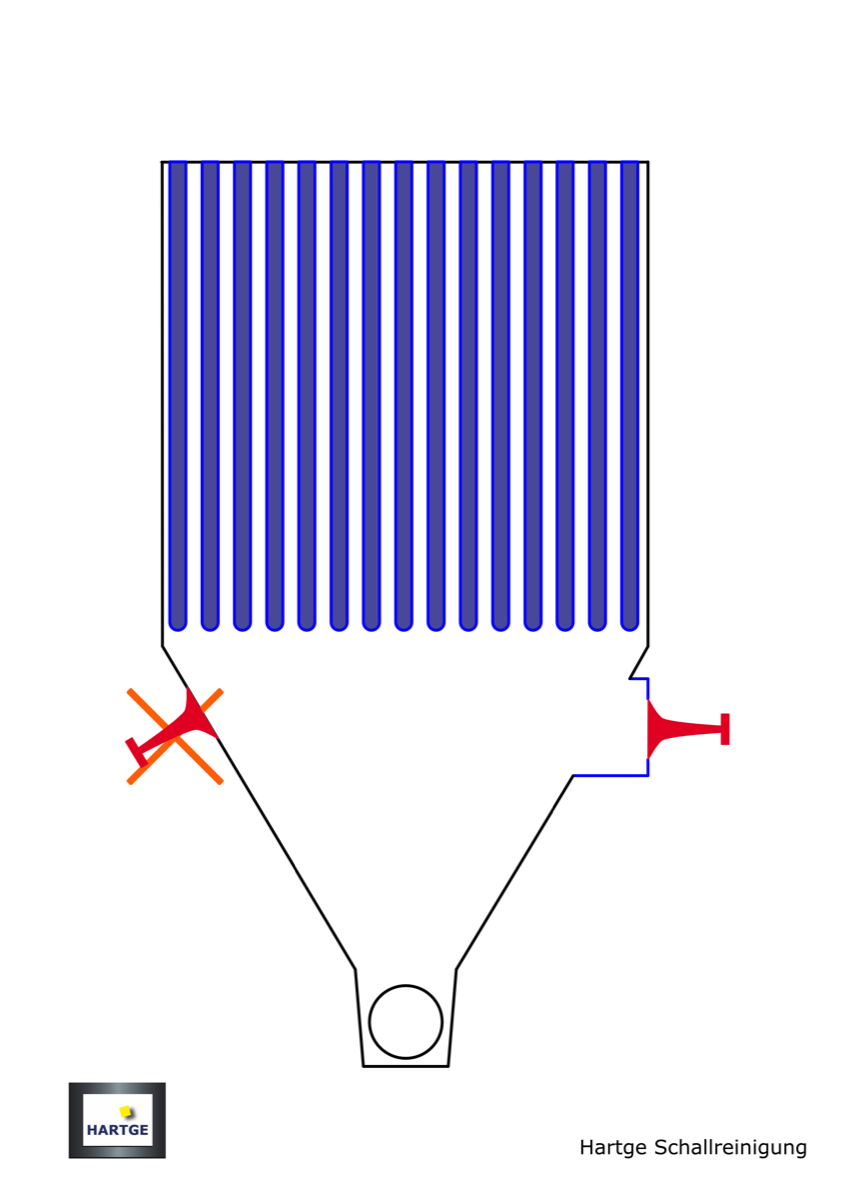

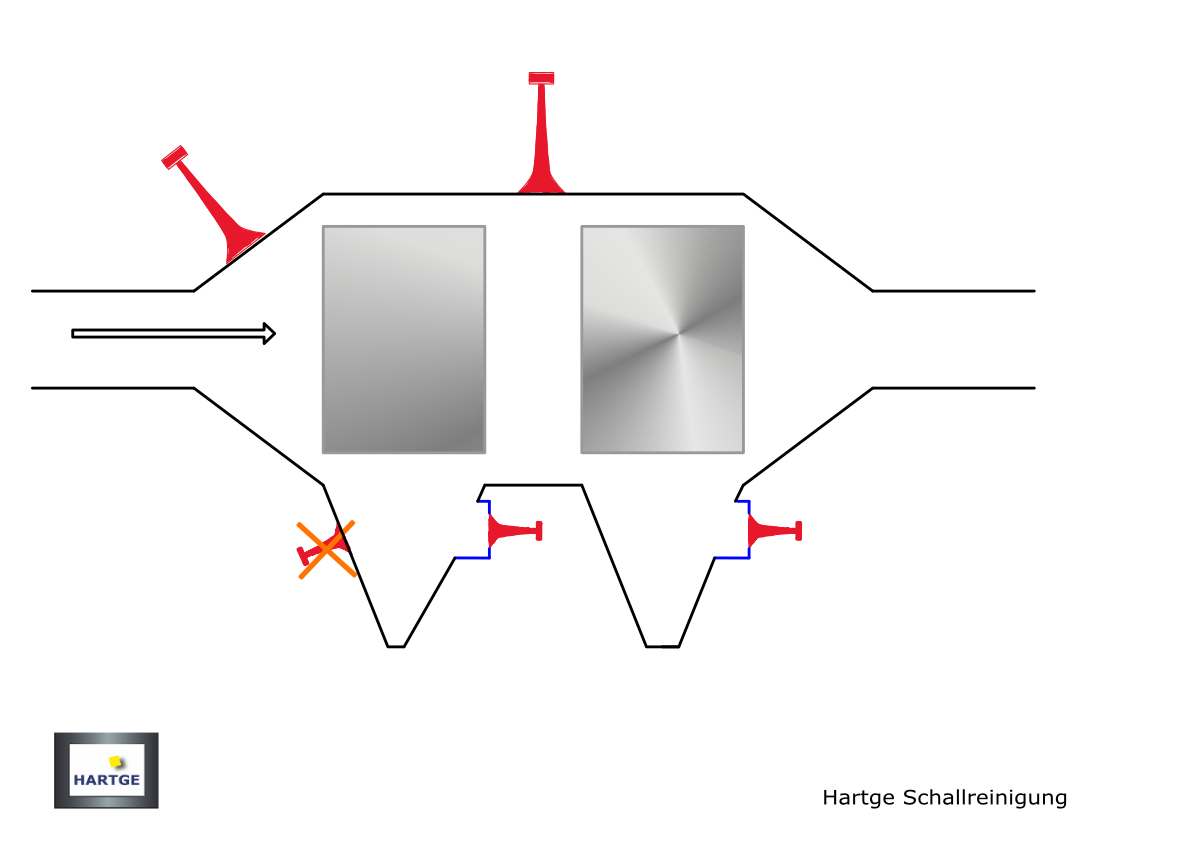

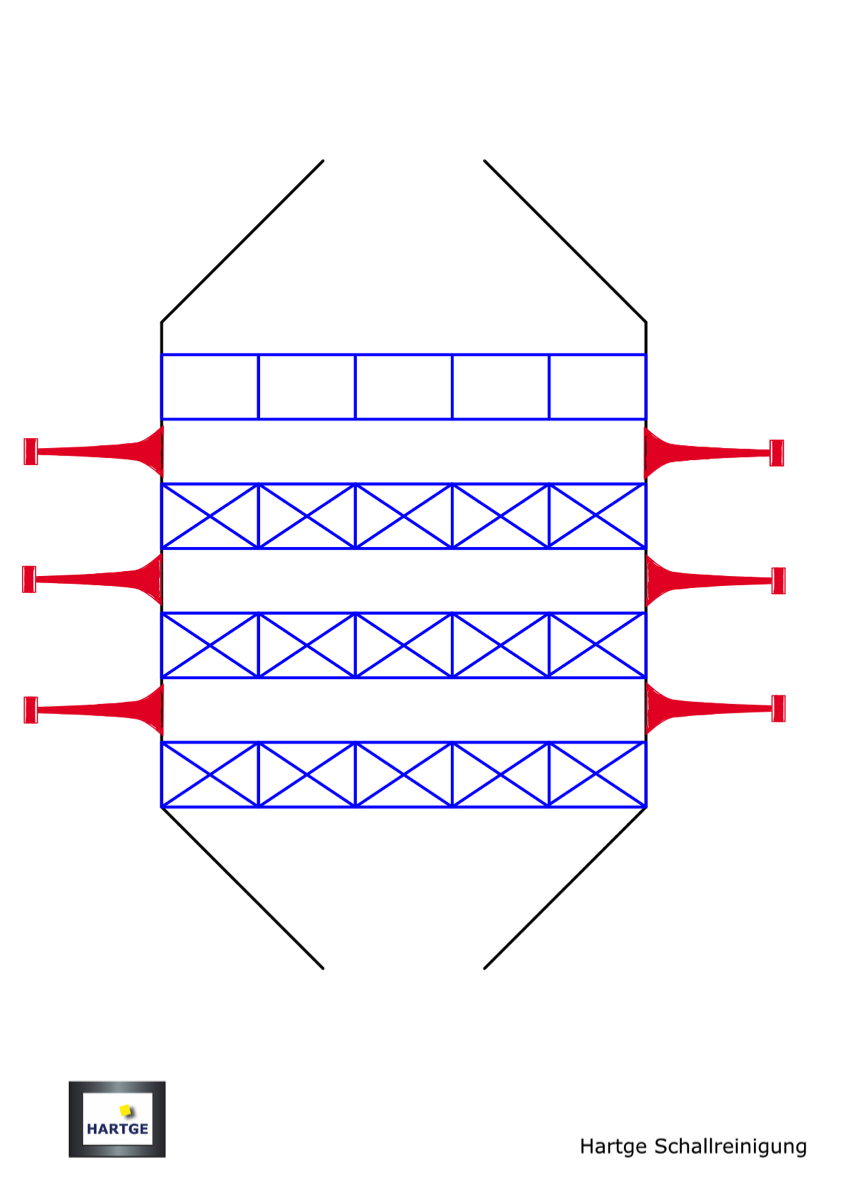

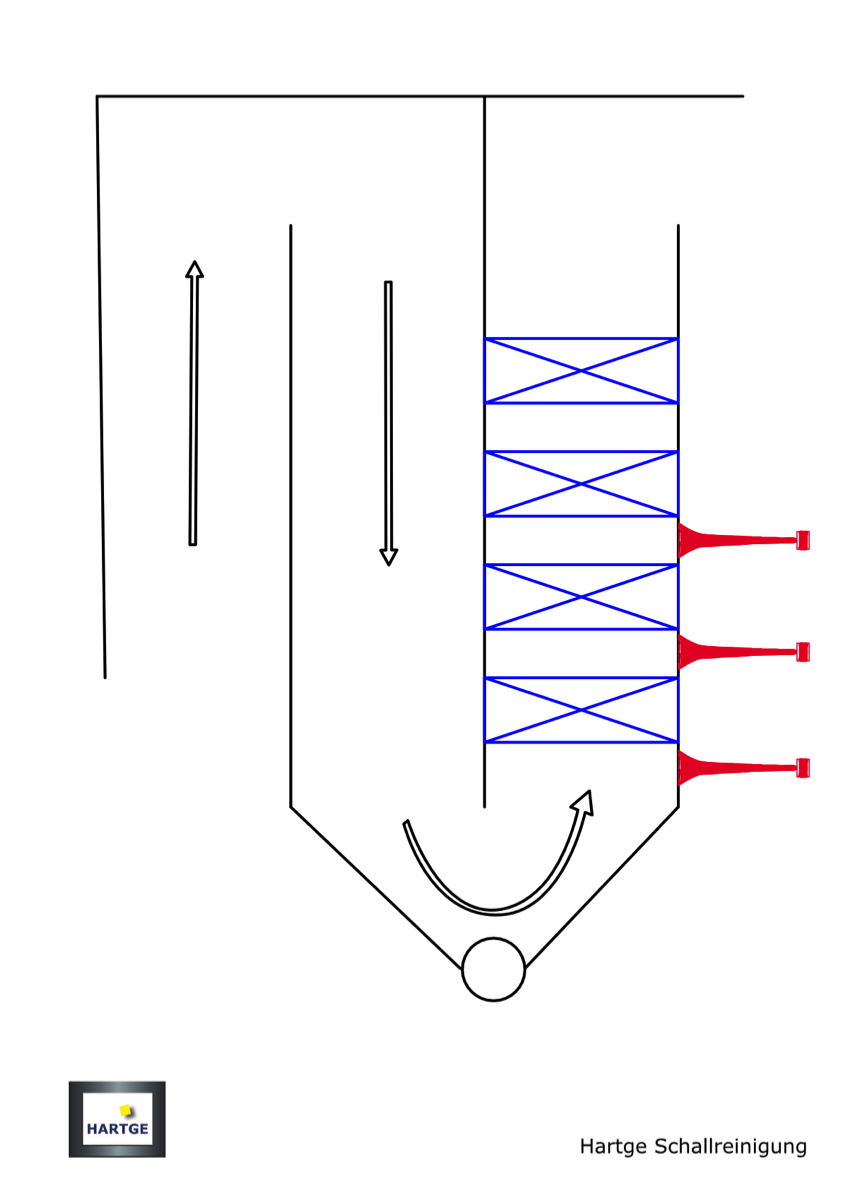

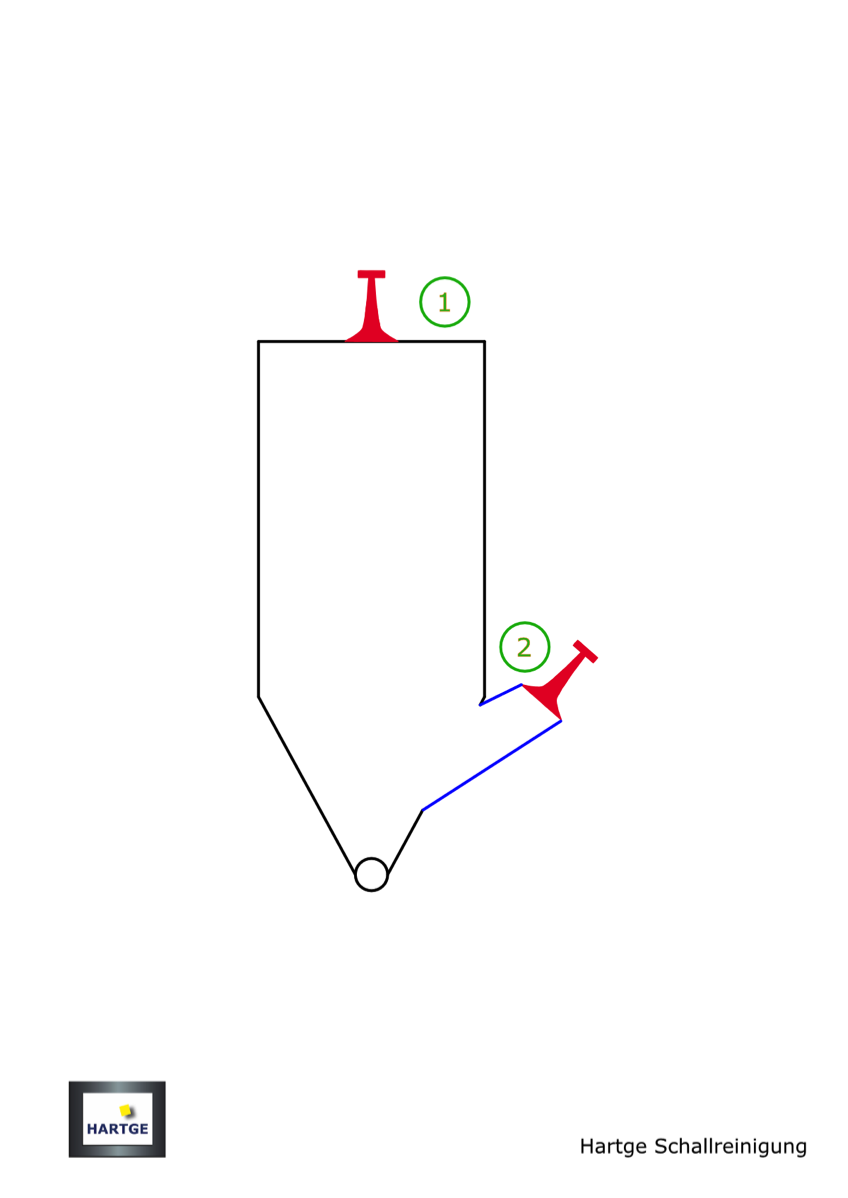

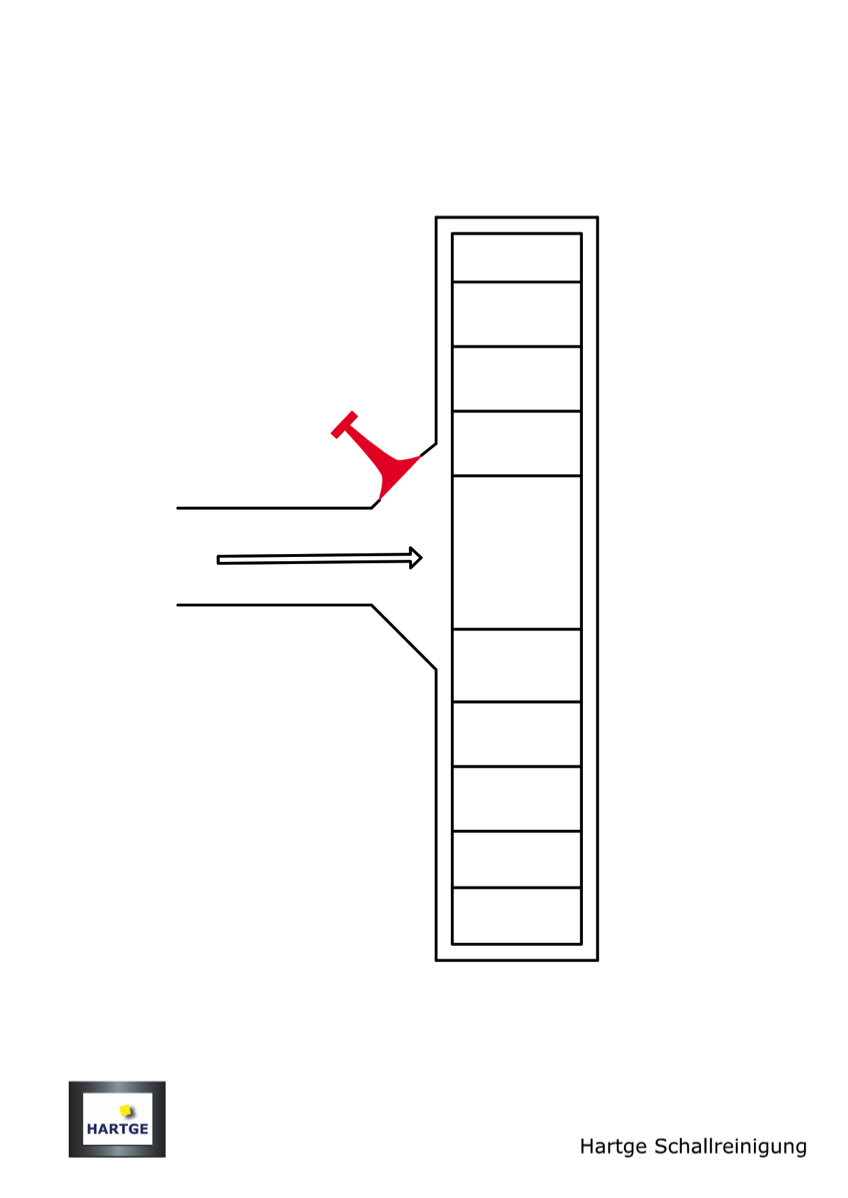

Caused by acoustic sound waves small parts of ashes and dusts will be put in vibration or kept in motion. Thus, claggy deposits will be prevented. For newly erected plants you better speak of ‚keeping clean‘ the system. As acoustic sound waves expand spherically, they can reach even the rear side of complex structures by reflection.

Acoustic cleaners were applied in the following branches: Biomass, pit-coal and lignite power plants Paper industry, chemical industry, food production, etc. These plant sections are favored: Economizer, air preheater, silo, hopper, filter systems, DeNO x (SCR), superheater

Questions? Simply call us: +49/172/4095620

Portfolio

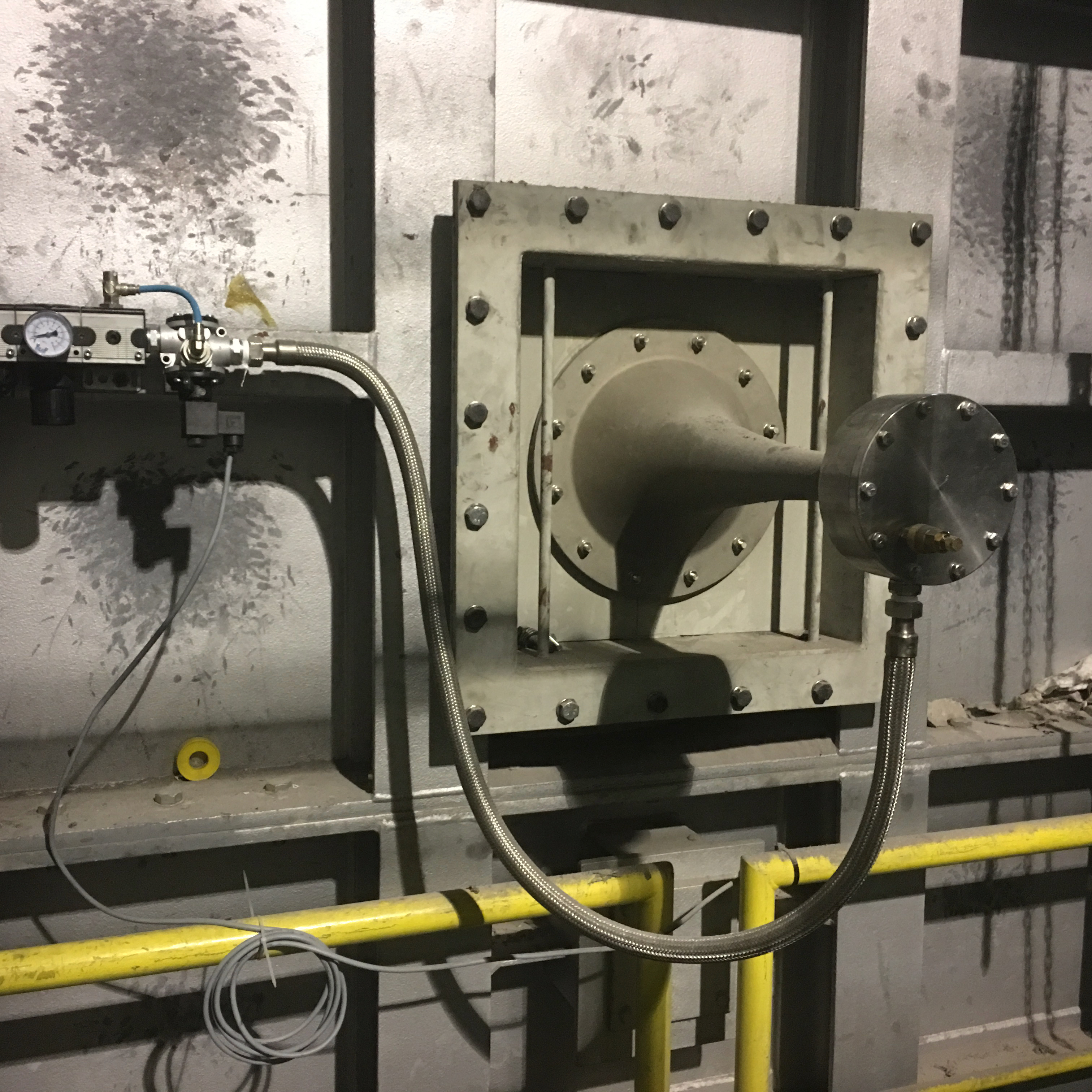

Hartge Schallreinigung offers different variants of sonic cleaners with different frequencies and outputs.

- Design: straight or 90° curved

- Generation of sound waves: by means of compressed air or electric drive

- Material: 1.4308, P265GH or according to customer requirements

- Frequencies: 60, 75, 100 and 250 Hz (compressed air) 30 - 100 Hz (electric)

The modular design and the use of different materials enable us to offer the right solution for every installation situation. Of course, we also offer special solutions: other materials, special alloys for HT areas and coatings against the risk of corrosion. The construction of prototypes serves the continuous improvement of our systems.

Thanks to this diverse range, we can guarantee installation for almost any situation on site.

Netzwerk

Strong partners at our side are:

Häuser & Co. GmbH from Duisburg

They specialise in coatings against corrosion and wear, both in the high-temperature range and when temperatures fall below the dew point. Using plasma and laser spraying processes ("LaserCladding"), materials and coatings are applied that are specially tailored to the stresses in the area of evaporator and superheater heating surfaces and can significantly increase the service life and availability of your systems.

Anif e.V. is a company co-operation of specialists who have joined forces in the field of industrial and combustion plants and who complement each other perfectly with their respective products in the field of power plants and combustion plants.